The definitive version of our sheet used to bond dissimilar materials, with a 50% global market share

Owing to advancements and developments in composite materials, the applications for these products are expanding every year from the automotive sector, building construction and sports accessories, to electronics and machining as well. In line with this, requirements regarding the ability to bond dissimilar materials have become even more severe. At ASK Holdings, we have developed our Asner Sheet products to solve these issues. This material has been widely appreciated not only in Japan but throughout the world of sports for over 40 years, and is used by around 50% of ski and snowboard manufacturers. We will continue to solve the problems of bonding different materials other than skis and snowboards.

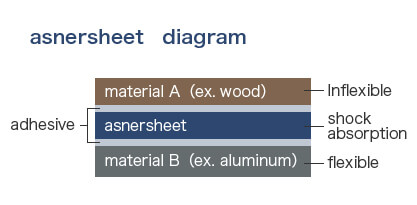

The Asner Sheet is a rubber sheet uniquely developed by ASK Holdings as an intermediate material used when bonding

dissimilar material together. The Asner Sheet improves the adhesiveness and water tightness of areas that are subject to

impact, and also absorbs slight vibrations. Further, since the sheet has a non-sticky surface, it can also be used as a

material for gaskets with minimal stickiness.

We can provide sample products. Please contact us.

Skis, snowboards, archery, clubs used in mallet-based golfing games, aluminum sashes, gravestones, CFRP + Steel

Golf shafts, earthquake-resistant reinforcing materials and sound insulation materials for buildings, sports accessories such as golf club heads

HEAD, elan, BURTON

| Thickness: |

0.15 mm (tolerance: -0.05 mm, +0.03 mm) 0.20 mm (tolerance: ±0.05 mm) 0.50 mm (tolerance: ±0.05 mm) 0.75 mm (tolerance: ±0.05 mm) 1.00 mm (tolerance: ±0.05 mm) 2.00 mm (tolerance: ±0.05 mm) |

|---|---|

| Colors: | Ivory white, gray |

| Notes: Single roll: | 150 m (0.15 t, 0.2 t), 40 m (0.75 t or more) - Can be cut to desired specifications (effective width: 7.5–500 mm) - Hole-punch processed sheets - Can be cut into specific shapes (generally supplied in rolls) |

| Material | SBR (styrene-butadiene rubber) |

|---|---|

| Hardness: | 65±5 |

| Cold tolerance Heat tolerance |

-30℃〜-60℃ 120℃ |

| Peel strength | 10 kg or more; *T-peel (25 mm width/kg) Adherent material: aluminum with aluminum |

Note: the peel strength data shown above reflects our full understanding as far as we can ascertain, but comes with no guarantees as to its reliability, nor implies any responsibility on our part as to the results of using this data.

Keep this material away from direct sunlight and dust. (Note that as the rubber material used in the Asner Sheet is stable, degradation is almost never a problem when the product is stored normally.)

The Asner Sheet is used as a buffer material when bonding dissimilar materials.

For example, when you try to apply an aluminum panel onto a wood surface, the material will come off when exposed to

impact. By using an Asner Sheet between the two materials, you can prevent them from peeling apart due to impact,

flexing, heat or other forces.

This material is widely used for products like skis and snowboards that need to stand up to repeated repelling forces, skis used in ski jumping that must hold up under strong forces of impact when the rider slides down high slopes and then

lands, and in the manufacture of sporting goods like rackets, shafts and so on.

Strength and characteristics of materials used for adhesion

| Epoxy | ○ | |

|---|---|---|

| Polyamide | × | |

| Resorcinol | ○ | |

| Urethane | ○ | Non-solvent type |

| Rubber | △〜○ | Solvent type The results for rubber-type products were evaluated as “fair” after 11 days had passed, and gradually moved in the “good” direction later. |

| Urea | ○ | |

| Polyvinyl acetate emulsion | △ | |

| Acrylic | ×〜○ | Differences exist within the range of “poor” to “good”, depending on the manufacturer and grade. |

| Cyanoacrylate | ×〜○ | Differences exist within the range of “poor” to “good”, depending on the manufacturer and grade. |

Evaluation criteria— “good”: Asner Sheet adhesive failure: 80–100%; “fair”: Asner Sheet adhesive failure: 20–80%;

“poor”: Asner Sheet adhesive failure: 0–20%

For rubber materials— “good”: peel strength of 6 kgf/cm; “fair”: peel strength of 1–6 kgf/cm; “poor”: peel strength of 1

kgf/cm

The Asner Sheet NW is an even more lightweight non-woven fabric version of the Asner Sheet, infused with SBR latex. This product is used in many sporting goods, with a vibration damping ratio that makes the difference. Your logo or other design can be printed directly onto the surface of the Asner Sheet NW, for use as a surface material.

Adhesive needs for skis, snowboards, archery, clubs used in mallet-based golfing games, aluminum sashes and gravestones

Golf shafts, earthquake-resistant reinforcing materials and sound insulation materials for buildings, sports accessories such as golf club heads

| Thickness: | 0.25 mm (tolerance: ±0.05 mm) |

|---|---|

| Color: | Ivory white |

| Notes: | Single roll: 250 m - Logos or other designs can be printed directly onto the surface of the Asner Sheet NW, - Can be cut to desired specifications (effective width: 15 mm–500 mm) - Can be cut into specific shapes (generally supplied in rolls) |

| Material: | SBR (styrene-butadiene rubber) latex + non-woven fabric |

|---|---|

| Peel strength | 8 kg or more; *T- peel (25 mm width/kg) Adherent material: aluminum with aluminum |

Note: the peel strength data shown above reflects our full understanding as far as we can ascertain, but comes with no guarantees as to its reliability, nor implies any responsibility on our part as to the results of using this data.

Keep this material away from direct sunlight and dust. (Note that as the material used in the Asner Sheet NW is stable, degradation is almost never a problem when stored normally.)

Composite materials are composed of two or more materials with different characteristics, which are strongly bonded

together at the surface to form a single compound material with enhanced strength, rigidity and lighter weight.

We are involved in developing products that make use of the adhesive qualities of our Asner Sheet, in response to

surface adhesion needs.

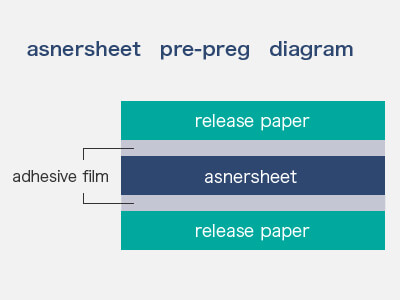

Pre-impregnated version of our rubber sheets used to bond dissimilar materials

| Resin type: | epoxy |

|---|---|

| Resinous content: | 60g/m² |

| Adhesive conditions: | 125℃×25min |

| Types of adherent material | Wood, paper honeycomb, acrylic foam, aluminum, metals such as stainless steel and magnesium, GFRP, CFRP |

Feel free to contact us if you’d like to

inquire about our products and services.

Business hours: 9:00 a.m.–5:30 p.m. weekdays

(excepting Golden Week, the summer holiday season, New Year’s holidays and days off specified by ASK